| Flex is excellent for textile heat transferring as it is highly flexible and tender with exceptional elongation and perfectly adhests to the textile with cracking-free capability. This film shows you how to heat-transfer an image on Flex to a T-shirt. A GCC Cutting Plotter, an Eco-Solvent Printer, a Heat Press Machine and some Flex is all you need to complete a customized T-shirt full of fun and creativity. | |||||||

|

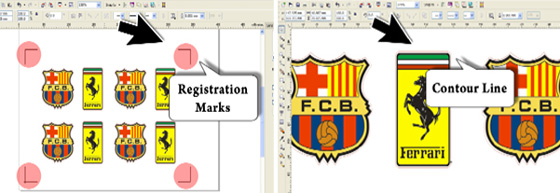

Step 1 Create an image with a contour line and registration marks on CorelDraw/ Illustrator and print it out on a heat transfer printable flex by an eco-solvent printer. | |||||||

| |||||||

|

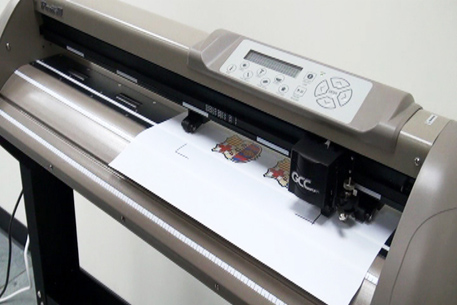

Step 2. Cut your image using a GCC cutting plotter. | |||||||

| |||||||

| Step 3. Firmly fix the printable flex on the heat transfer backing and remove the backing. | |||||||

|

|||||||

| Step 4. Place a Teflon sheet over the T-shirt and press the heat transfer backing with the printed image on the T-shirt using a heat press machine at 150℃ for 15 seconds. | |||||||

| |||||||

| Now you have a customized T-shirt for yourself, or friends and families. | |||||||

| |||||||

| From: Craft Magic Trading | |||||||

With 10 years of marketing & technical experience, we have became a full range supplier of office equipment and machines for the fast print and advertising industry, Rubber Stamp, including t-shirt heat press in Premium & Gifts sector, to fulfill our customers' needs.

Monday, 29 October 2012

Printable Flex Heat Transferring with GCC Cutting Plotters

Labels:

GCC Plotter